The mold injection method making use of thermal reversibility is adopted for the processing.

Because mass production is possible, it is suitable for general buttons. The buttons which are combined with metal parts and others are more popular than the ones made from nylon resin single material now. Here is the features of the material

Because it cannot be dyed later, we color it at the stage of raw material. We pile up the material boards while matching colors and patterns, and then transform them to small round sticks by putting pressure and heat on them with the extrusion machine, push them out and cut them into round slices at the exit. Then, after regulating its water amunt, we put them in the dies of compacting machines, compress and heat them, and then they get transformed into the shape of buttons. After that we dry and polish them after removing the burr (unnecessary thing which protruded from the gaps of dies).Here is the features of the material

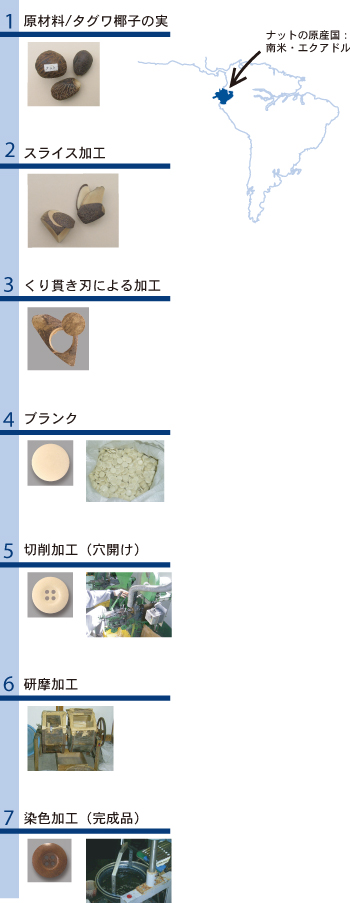

Because the fruit shows its beautiful ivory flesh of fruit when its skin is peeled off, it is called "an ivory nut".

It has the soft touch only special to natural material in both points of material texture and luster. It is a superior material being easy to treat like easy to dye and process as well. Here is the features of the material

After the necessary processing is given to the hides it is cut small and knit a button . The form is fixed with press working. They are painted with paint, and made buttons called basket style.Here is the features of the material

To make the material, we first put white pigment, pearl foil (this is put in to get the colored pattern like a pearl when it becomes the product), water and others into the raw material and mix them, then leave it to age for twenty-four hours, put it in a pushing out machine and knead it thoroughly with heat and pressure, and push it out. We can make materials with patterns and shapes of round stick, or belt by changing the shape of the part at the exit.Here is the features of the material

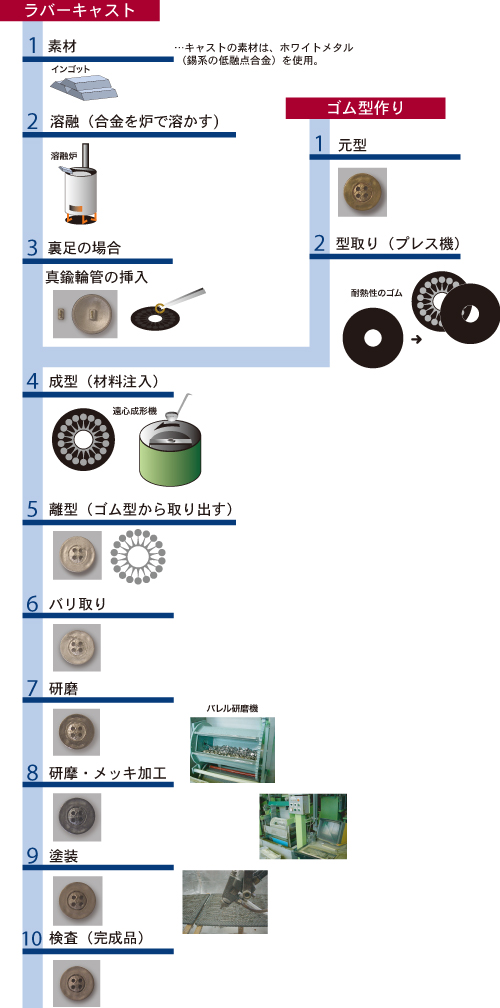

In addition, if there is one archetype, it is possible to make rubber molds and produce in large volume with them.Here is the features of the material

Because it has the property that it can spread, it is possible for both press working and cutting work..Here is the features of the material