Polyester buttons are made from unsaturated polyester resin, a petroleum-derived material. The resin is liquid and cures at room temperature, which makes it easy to process. Because of its thermosetting properties, polyester has long been widely used for apparel buttons.

In 1955, a manufacturing technique was developed in the United States that used polyester resin to reproduce the glossy luster of shell. This innovation quickly replaced acrylic, which had been the mainstream material up to that point, and polyester buttons spread to Japan as a substitute for shell buttons. Today, polyester accounts for a large share of button production not only in Japan but worldwide.

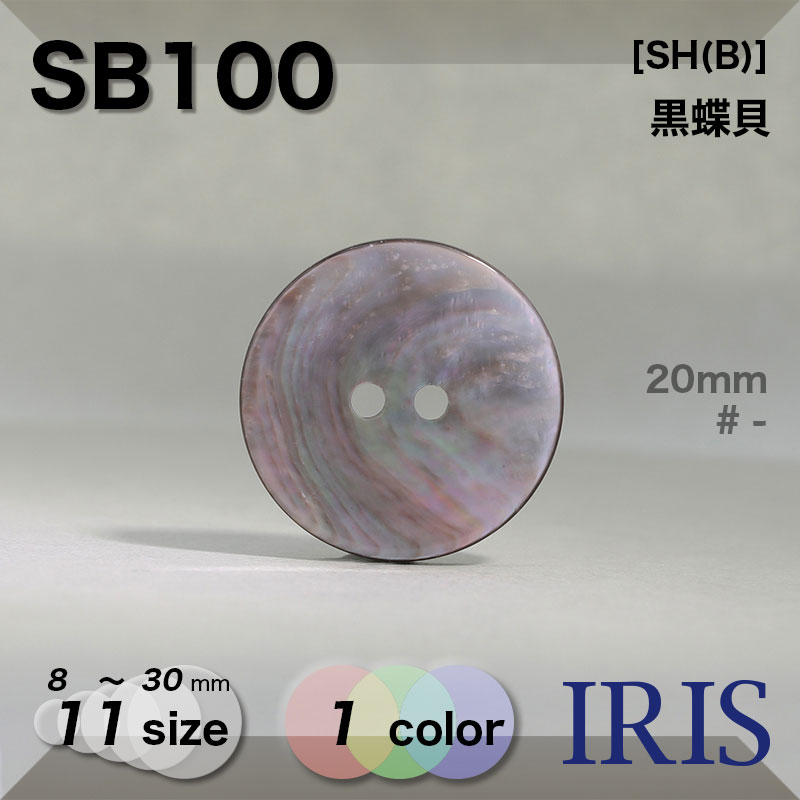

Because polyester’s colour can be freely adjusted, it can be used to imitate buffalo horn, shell, corozo nut, and many other materials. This flexibility allows for a wide range of designs. Manufacturing methods vary depending on the material being reproduced: one common technique is to pour resin into aluminum pipes to create patterned rods for button blanks, while another is to pour it into large drums over a meter in diameter, where centrifugal force forms layered sheets. In addition to single-material designs, polyester is also often combined with other materials such as metal, acrylic, or shell to create buttons with even greater variety and appeal.